Environmentally Compatible Design

July 17, 2024

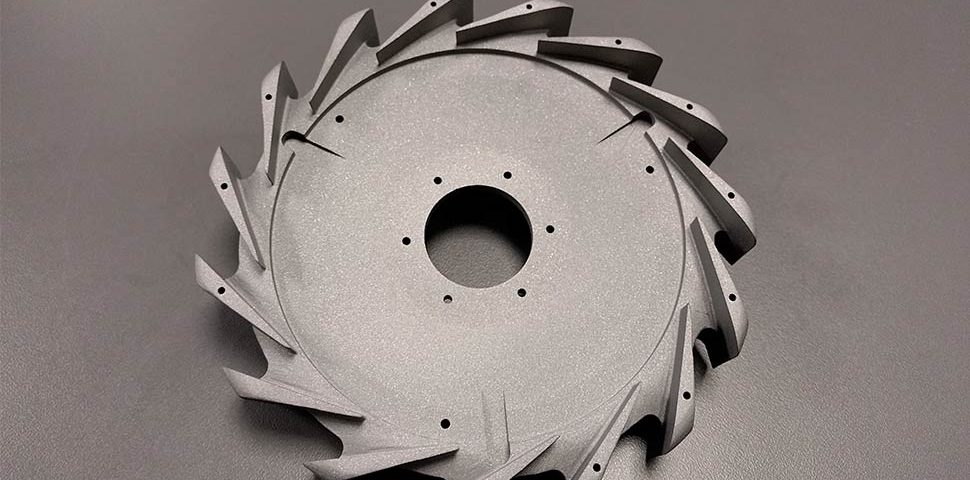

sustainable development in additive manufacturing

July 19, 2024Additive manufacturing, or 3D printing, has garnered significant attention in Iran in recent years. Utilizing advanced processes, this technology enables the production of complex and customized parts applicable across various industries such as automotive, aerospace, medical, and even art. Iranian companies and universities are actively striving to develop and enhance this technology. Iran has succeeded in producing some of the necessary raw materials for 3D printing and is working on developing indigenous machinery and software in this field.

Given the growing trend of additive manufacturing technology in Iran, the future of this industry looks very promising. Both the government and the private sector are investing in research and development. Plans are underway to establish specialized research and educational centers, which could help train skilled personnel and boost domestic capabilities. Additionally, startups are offering innovative solutions, aiming to secure a share of this burgeoning market.

However, there are challenges in the path of developing additive manufacturing in Iran, including the need for high-quality raw materials, the high cost of equipment, and the necessity for technology transfer from more advanced countries.

Despite these challenges, with recent advancements and ongoing projects, it appears that Iran could soon become a significant player in additive manufacturing in the region, leveraging this technology to increase productivity and reduce costs across various industries.

History and Development of Additive Manufacturing in Iran

The history and development of additive manufacturing technology in Iran dates back to recent decades. The initial efforts to introduce and utilize 3D printing in Iran began in the early 2000s. Universities and research centers started studying and examining this technology, gradually bringing the first 3D printers into the country, primarily for research and educational purposes.

One of the pioneering institutions in this field was Sharif University of Technology, which, in collaboration with domestic and international companies, established specialized laboratories in this area.

This university played a crucial role in training specialists familiar with modern technologies.

Additionally, other centers such as Iran University of Science and Technology and the University of Tehran also entered this field, contributing to the development of this technology through educational and research programs.

In the mid-2010s, with the rapid growth of technology and increasing demand for 3D printed products, the additive manufacturing market in Iran began to expand. Private companies entered the scene, aiming to meet the needs of various industries by importing and producing 3D printers. These companies offered a range of services, including design, prototyping, and final part production, establishing their presence in the market and gradually becoming key players in the development of this technology in the country.

One of the most significant achievements of this period was the production of indigenous 3D printers. Iranian engineers and researchers, relying on domestic knowledge and global experiences, succeeded in designing and manufacturing high-quality, competitively priced 3D printers.

These machines not only met domestic demands but also penetrated regional markets, capturing a share of the global market. The development of raw materials used in 3D printing was another area of research and development that contributed to the advancement of this technology.

Nowadays, Iran has become one of the leading countries in the region in additive manufacturing. Despite challenges such as the need for more advanced technologies and higher quality raw materials, Iran has managed to continue developing and expanding this technology through strategic planning and continuous investment.

The future of this industry in Iran appears bright, and with ongoing efforts in research and development, it is expected that Iran will become one of the key players in the field of additive manufacturing globally.

Recent Developments

In Iran, significant progress has been made in the field of additive manufacturing, largely due to government support. The government has recognized the economic and industrial growth potential of these new technologies and has implemented numerous programs and policies to foster their development.

These programs include facilitating the import of advanced equipment, encouraging domestic production, and supporting research projects. By providing appropriate legal and financial frameworks, the government has aimed to remove barriers for companies and researchers, creating a conducive environment for the advancement of this field.

One of the government’s key initiatives in this area has been allocating research budgets and creating special support funds for the development of additive manufacturing technologies. These funds are primarily directed at universities, research centers, and knowledge-based companies to conduct practical and innovative research that contributes to the development and improvement of this technology.

Additionally, financial support programs such as low-interest loans and tax exemptions for companies active in this field have increased private investment and international partnerships.

Furthermore, the government has tried to simplify the production and commercialization processes of additive manufacturing technology through appropriate laws and regulations. These laws include facilitating patent registration, protecting intellectual property rights, and establishing national standards for 3D printed products. The aim of these actions is to create a secure and stable environment for research and commercial activities in this field, which can attract investor confidence and accelerate technology development.

The government has also enhanced public knowledge and awareness through conferences, exhibitions, and educational workshops related to additive manufacturing technology. These events provide excellent opportunities for the exchange of information and experiences among researchers, industry professionals, and policymakers, fostering strategic partnerships and collaboration networks. This way, the scientific and industrial community of the country can stay informed about the latest achievements and global trends in this field and use them for improvement and progress.

Ultimately, the government’s role in supporting the development of additive manufacturing in Iran extends beyond policies and laws, including the creation of appropriate infrastructure. By investing in science and technology parks, innovation centers, and advanced laboratories, the government has tried to provide the physical and technological foundations necessary for the growth and prosperity of this technology.

These infrastructures enable companies and researchers to access advanced equipment and suitable research environments, develop new products and processes, and compete more effectively in domestic and international markets.

Challenges and Obstacles

Despite all the advancements, additive manufacturing technology in Iran still faces many challenges and obstacles. One of the biggest problems is the supply of high-quality and diverse raw materials. Many materials used in 3D printing, such as specialized polymers, metals, and ceramics, are limited and expensive. The import of these materials is also complicated by issues such as international sanctions and currency restrictions, making access to quality and affordable materials difficult.

Another significant challenge is the shortage of technical knowledge and expertise in the field of additive manufacturing. Despite government and university efforts to educate and train specialized personnel, there is still a lack of necessary skills in design, engineering, and practical applications of this technology. Many companies and industries require specialized training and workshops to improve their employees’ skills, leading to reduced productivity and increased production costs.

Additionally, the high cost of 3D printing equipment and machinery is a major obstacle to the development of this technology in Iran. Advanced, high-precision devices typically come with high prices, which are not affordable for many small and medium-sized enterprises. Maintenance and repair of these devices also require expertise and spare parts, which are challenging to obtain in Iran. This issue makes it difficult for many industries and companies to easily adopt this technology.

Finally, the lack of appropriate infrastructure for the development and commercialization of additive manufacturing technology is another obstacle. Despite government efforts to create science and technology parks and innovation centers, there are still deficiencies in this area. Many companies need access to advanced laboratories, international cooperation networks, and more financial support.

These infrastructures can accelerate the research and development process and increase the competitiveness of Iranian companies in global markets. By addressing these challenges and obstacles, Iran can become one of the leading countries in additive manufacturing and leverage the benefits of this technology to improve various industries.

The Future of Additive Manufacturing in Iran

The future of additive manufacturing in Iran looks very promising given the country’s significant potential. One of the most important opportunities is leveraging the young and educated workforce.

Iran has a large number of graduates in engineering and technology fields who can play a crucial role in the research, development, and implementation of additive manufacturing technology. With substantial investment in education and research, Iran can cultivate a new generation of specialists capable of leading advanced projects.

Another important opportunity is the large domestic market. With the growing needs of various industries such as automotive, aerospace, medical, and defense, additive manufacturing can provide a solution for producing complex and customized parts at lower costs and shorter production times. Utilizing this technology can reduce dependency on imports, improve the quality of domestic products, and enhance the competitiveness of Iranian industries in global markets.

Additionally, Iran can benefit from developing international collaboration networks and drawing on the experiences and knowledge of leading countries in this field. Establishing strategic partnerships with foreign companies and research centers can provide access to advanced technologies and higher quality raw materials.

These collaborations can facilitate technology transfer and accelerate the localization process. Furthermore, Iranian companies can participate in international conferences and exhibitions to stay updated on the latest trends and achievements in technology and use them to improve their products and processes.

Ultimately, government support and appropriate policy-making can play a significant role in the growth and development of additive manufacturing technology in Iran. The government can accelerate the development of this technology by creating suitable legal frameworks, facilitating investment processes, and providing financial and credit facilities to companies active in this field.

Establishing specialized science and technology parks and innovation centers will provide the necessary infrastructure for research and development and attract domestic and foreign investments.

By leveraging these opportunities and capacities, Iran can become one of the regional leaders in additive manufacturing and use the benefits of this technology to improve various industries.

International Experiences

The future of additive manufacturing in Iran can significantly improve by leveraging international experiences. Many leading countries in this field, including the United States, Germany, and China, have achieved considerable development and progress by adopting strategic approaches and precise planning.

These countries have created the necessary infrastructure for the growth of additive manufacturing by making substantial investments in research and development, establishing extensive collaboration networks between universities, research centers, and industries, and providing financial and legal support to innovative companies.

The United States is one of the countries that has achieved significant success in additive manufacturing by establishing advanced research centers and investing in the training of specialized personnel.

Programs such as “America Makes,” a national consortium for the development and research of additive manufacturing, exemplify these efforts. Iran can model such programs by creating similar consortia involving close collaboration between the government, universities, and industry to expedite practical research and technology development.

Germany has also achieved significant progress in additive manufacturing through collaboration between industries and research centers. The “Fraunhofer Institute,” one of the world’s largest research organizations, has established specialized research centers in this field and fostered strategic collaborations with leading global companies.

Iran can model this approach by promoting closer cooperation between universities, research centers, and private sector companies and creating opportunities for knowledge exchange and technology transfer.

China has also experienced significant advancements in additive manufacturing by establishing science and technology parks and special economic zones. These zones provide financial and credit facilities, tax exemptions, and advanced infrastructure for companies active in this field.

Iran can model this approach by creating specialized zones for the growth and development of additive manufacturing and providing companies with suitable facilities and support for innovation and research.

By learning from the successful experiences of other countries and adopting strategic and systematic approaches, Iran can accelerate the growth and development of additive manufacturing technology and leverage its benefits to improve various industries and enhance competitiveness in global markets.

Proposed Solutions:

To accelerate and enhance the development of additive manufacturing technology in Iran, policymakers and stakeholders should focus on several key areas. The first recommendation is for the government to provide increased financial support and incentives. Establishing dedicated funds for research and development in this sector, offering low-interest loans to startups and knowledge-based companies, and reducing taxes for companies engaged in additive manufacturing can create the necessary incentives for investment and innovation. These measures can help reduce costs and increase the competitiveness of domestic industries.

The second recommendation is to focus on education and training of specialized human resources. Policymakers should establish comprehensive and effective educational programs in universities and technical centers that provide students and professionals with specialized training in design, engineering, and practical applications of additive manufacturing technology. Creating internship programs and fostering close collaboration with industries can help enhance the practical and experiential skills of students. Additionally, organizing international workshops and seminars with the participation of foreign experts and specialists can facilitate the transfer of global knowledge and experience to the country.

The third recommendation is to strengthen research and development infrastructure. The government and private sector should invest in the establishment and development of science and technology parks, innovation centers, and advanced laboratories. These infrastructures should be equipped with state-of-the-art equipment and technologies to enable researchers and companies to easily conduct advanced research and develop innovative products. Furthermore, creating international collaboration networks with leading research centers and companies worldwide can facilitate the exchange of knowledge and experiences and expedite the development process of the technology. By considering these recommendations, Iran can pave the way for progress in additive manufacturing and become one of the leaders of this technology in the region.