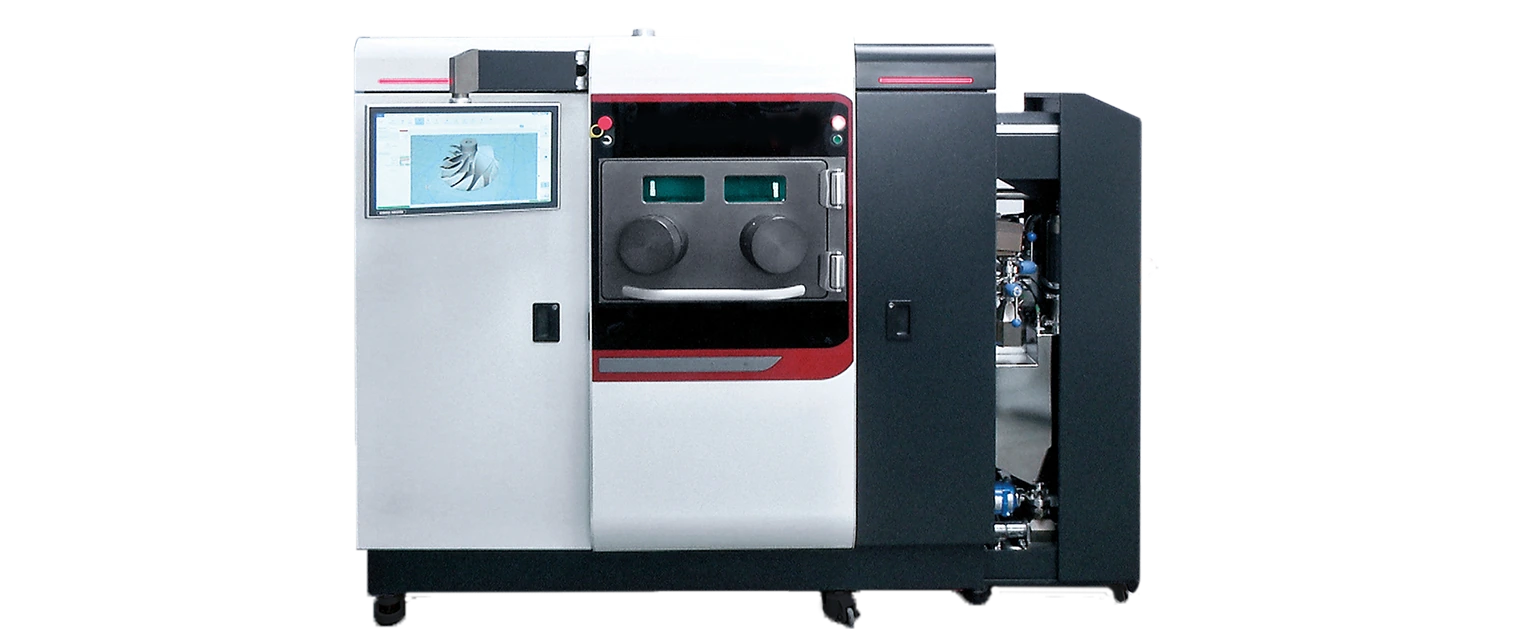

Metal 3D Printing Machines

3D printing has changed the dynamics of multiple industries, such as healthcare, automotive, aerospace and industrial design. This is an ever changing technology that works well when used to make difficult metal parts in a very accurate way. Selective Laser Melting (SLM) is at the heart of this technology where the objects made by 3D metal printing are obtained by selectively melting metal powder with a highly focused laser beam.

History:

SLM was first introduced in the 1990s and has since witnessed remarkable advancements. Initially, intended for prototyping, it has now become a valid method for producing final parts.

SLM Process:

In SLM process, a thin layer of metal powder is first applied to the work surface. Then a high-precision laser melts only selected parts of this powder layer according to provided 3D design. These melt and solidify quickly when cooled down while another layer of metal powder gets added on top. This keeps going until the entire shape is done.

Materials Used:

Titanium, steel, aluminum or special alloys could be among metallic powders utilized in SLM manufacture. Materials are selected based on physical and engineering properties required for part like heat resistance, strength and bio-compatibility.

Benefits:

SLM allows for the creation of intricate and tightly tolerance parts that might not be possible with traditional methods. In addition, it is a greener technology which has seen reduction in material wastage and improved productivity.

Design Freedom

Independence of Creation:

3D printing machines are free from manufacturing and assembly requirements thus making it possible for designers to shape out difficult figures that would otherwise be impossible or impractical. This technology provides fresh avenues of producing intricate lattice structures, paper thin walls and complex voids aimed at reducing weight of materials.

Sustainable Development & Innovative Architecture:

Architecturally, 3D printing is used to explore sustainable responsive designs by considering environmental impacts and other societal aspects.

Customizing Costs:

With increasing demand for customized products; 3D printing machines have enabled manufacturers to easily adapt to such requests cost-effectively, ranging from industrial parts to consumer goods with custom-made patterns.

Sustainable development

Optimized Production:

By 3D printing, there is the optimization of material use, thereby reducing waste and minimizing costs. It follows that this additive manufacturing method allows for production of products only from the amount required for their making without any additional waste being produced.

Product Design Based on Lifecycle:

With 3D printing machines, it becomes possible to design and make products taking into account their whole life cycle with design modifications that will enhance recycling process as well as decrease environmental impacts at consumption and disposal levels.

Accuracy And Efficency

Technological advancements and advancements, in precision;

methods of 3d printing such as FDM (Fused Deposition Modeling) SLA (Stereolithography) and SLS (Selective Laser Sintering) each have their own level of accuracy. SLA and SLS are commonly chosen for applications that demand results due, to their capability to print intricate details with great finesse.

Technological innovations:

New printing heads, advanced printing processes and improvement of material quality are among recent developments in 3D printing technology which contribute to enhanced precision and effective performance.

Energy efficiency and durability:

Another dimension of effective performance in a 3D printing machine is its energy efficiency and durability. Devices that run on less energy and require less maintenance are more cost-effective for businesses in the long run and have a positive impact on the environment.

Reduce delivery time

Rapid prototyping:

One of the biggest advantages of 3D printing is its ability to quickly produce prototypes. This possibility allows designers and engineers to quickly imagine, produce and test their ideas. Reducing prototyping time increases the speed of product entry into the market.

On-demand production and reduction of storage time:

3D printing enables on-demand production. This means that companies no longer need to stock large quantities of parts and products, which helps to significantly reduce lead times and improve cash flow.

Responding to market changes:

In business environments where demand changes rapidly, 3D printing machines give manufacturers the power to respond quickly to changing demand. The ability to change products without the need for extensive changes to the production line makes it possible to reduce delivery time and increase production flexibility.

Customization and Immediate Production:

3D printing machines enable manufacturing of unique products on demand and instantly. This feature makes it possible for companies to meet the individual requirements of customers without spending a lot of time making huge measurements or expensive molds.

Improved Efficiency and Reduced Human Error:

Additive manufacturers have improved efficiency, as well as reduced human errors that come with manual operations. These factors coupled with repeatable parts’ accuracy are credited for shorter lead times and high quality.

Conclusion:

With metal 3D printing machines that use SLM technology, digital prototypes become real objects. This new technology facilitates future innovation due to its customization at very high levels of accuracy throughout different sectors resulting in better performance.